Segmented Turning

Coordinator

Ann Ormshaw

Contact Ann on: 0400 681 242

Segmented Turning Sessions

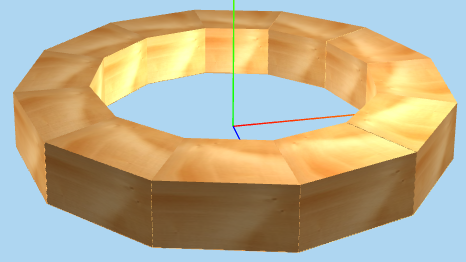

Segmented turning is the creation of a bowl, vase or similar object by the assembly of small wooden segments.

The segments must be accurately cut and assembled into rings. The rings are stacked and turned into the desired object.

The process of segmented turning commences by a detailed drawing on graph paper, of the item to be constructed, to determine the

number of segments per ring, the radius and height of each ring, the width of the segment and the wood to be used.

The number of segments per ring will determine the angle of the segment and therefore the 'mitre angle' the actual cut angle for the segment.

In summary, the process of segmented turning involves;

- Plan the project

- Machine flat strips of timber

- Cut into segments

- Glue segments into rings

- Stack the rings

- Build and turn the desired object

Various computer programs are available but I would recommend that club members use the 'Segmented Turning Helper Software' written by John Di Stefano. The software is very easy to use and presents a table of values very similar to what you would create on paper if you were doing the calculations manually. In addition the local support by John is most important. See the link below for full documentation and access to the software.

Segmented Turning Helper Software

Segmented Turning Helper Documentation

Maps:

Maps: